Milking represents one of humanity’s oldest agricultural practices, evolving from simple hand-squeezing techniques to sophisticated automated systems that can process hundreds of animals per hour. Understanding the various types of milking methods is essential for anyone involved in dairy farming, agricultural education, or simply curious about how milk reaches our tables. This comprehensive guide explores the different approaches to milk extraction, their advantages, disadvantages, and applications across various farming operations.

Table of Contents

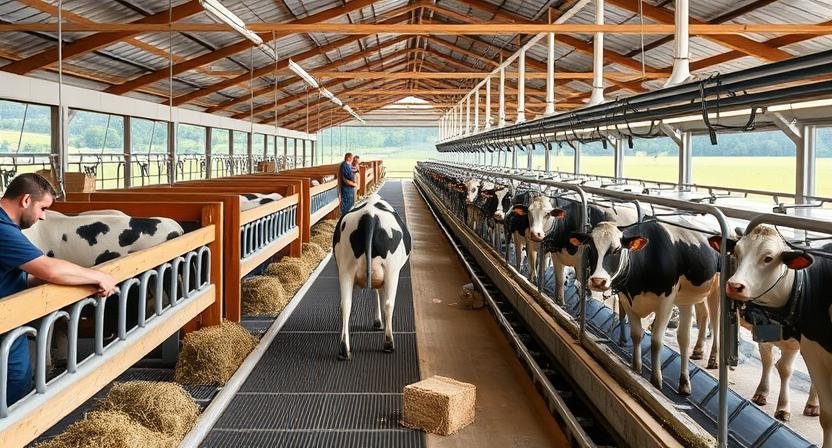

Hand Milking: The Traditional Foundation

Hand milking remains the most fundamental approach to extracting milk from dairy animals. This ancient technique involves manually stimulating the teats to release milk, typically into a bucket or container placed beneath the animal. Despite being labor-intensive, hand milking continues to play a vital role in small-scale farming operations, particularly in developing regions and among farmers who prioritize traditional methods.

The process requires significant skill and physical stamina. Experienced milkers can extract milk efficiently while maintaining animal comfort and milk quality. Hand milking allows for intimate animal interaction, enabling farmers to detect health issues early through tactile examination of the udder and teats. This method also provides complete control over milking speed and pressure, which can be particularly beneficial for animals with sensitive udders or those recovering from injuries.

However, hand milking presents several challenges. The technique demands considerable time investment, making it impractical for large herds. Physical strain on the milker’s hands, wrists, and back can lead to repetitive stress injuries over time. Additionally, maintaining consistent hygiene standards becomes more challenging without automated cleaning systems, potentially affecting milk quality and safety.

Machine Milking: Mechanized Efficiency

Machine milking revolutionized dairy farming by introducing mechanical vacuum systems that simulate the natural sucking action of calves. These systems consist of vacuum pumps, pulsators, and teat cups that attach to the animal’s udder. The vacuum creates suction that draws milk through the system into collection vessels or directly into bulk tanks.

Basic milking machines significantly reduce labor requirements compared to hand milking while maintaining consistent vacuum pressure and milking speed. This consistency often results in more complete milk extraction and reduced milking time per animal. Modern milking machines incorporate various safety features, including automatic shut-offs that prevent over-milking and potential udder damage.

The technology behind machine milking continues advancing, with modern systems featuring programmable controls, individual animal identification, and automated milk measurement. These enhancements allow farmers to monitor individual animal production, detect health issues through milk flow patterns, and optimize milking routines for maximum efficiency and animal welfare.

Milking Parlor Systems: Centralized Operations

Milking parlors represent a significant advancement in dairy facility design, creating dedicated spaces specifically engineered for efficient milk extraction. These specialized buildings house multiple milking stalls arranged in various configurations, allowing farmers to milk several animals simultaneously while maintaining ergonomic working conditions.

Herringbone parlors feature angled stalls that position animals at 45-degree angles to the central operator pit. This design provides easy access to udders while maximizing space efficiency. Parallel parlors align animals side-by-side, offering excellent udder visibility and access. Rotary parlors employ rotating platforms that continuously move animals through the milking process, enabling non-stop operation for high-volume facilities.

Modern parlor systems integrate sophisticated automation, including automatic teat cleaning, pre-milking stimulation, and post-milking teat dipping. Computer systems monitor individual animal performance, milk quality parameters, and facility operations. These technological integrations significantly improve milking efficiency while reducing labor requirements and human error.

Robotic Milking: Autonomous Innovation

Robotic milking systems represent the cutting edge of dairy technology, employing automated robots that milk cows without direct human intervention. These systems use advanced sensors, artificial intelligence, and mechanical precision to identify individual animals, clean teats, attach milking equipment, and monitor milk quality in real-time.

The primary advantage of robotic systems lies in their ability to operate continuously, allowing cows to be milked multiple times per day according to their natural rhythms rather than fixed human schedules. This flexibility often increases milk production while improving animal comfort and welfare. Robots can also collect detailed data about each animal’s health, production patterns, and behavior, providing valuable insights for herd management decisions.

However, robotic systems require substantial initial investments and ongoing technical support. The complexity of these systems demands specialized knowledge for maintenance and troubleshooting. Additionally, not all cows adapt well to robotic milking, requiring careful animal selection and training programs.

Mobile Milking: Flexibility in the Field

Mobile milking units bring milking capabilities directly to grazing animals, eliminating the need to transport animals to fixed facilities. These self-contained systems typically mount on trailers or trucks and include vacuum pumps, collection tanks, and power generation equipment.

This approach proves particularly valuable for pasture-based dairy operations, organic farms emphasizing grazing, and operations with multiple grazing locations. Mobile systems reduce animal stress associated with daily movement to milking facilities while allowing farmers to maximize pasture utilization.

The flexibility of mobile milking enables farmers to adapt to seasonal grazing patterns, weather conditions, and changing land use requirements. However, these systems generally have lower throughput capacity compared to fixed installations and may face challenges with power generation and milk storage in remote locations.

Pipeline Milking: Direct Transport Systems

Pipeline milking systems transport milk directly from the animal to bulk storage tanks through sealed pipeline networks. These systems eliminate the need for individual milk containers and reduce milk handling, thereby minimizing contamination risks and labor requirements.

Low-line pipeline systems transport milk at cow level through pipes running beneath the milking area. High-line systems elevate milk transport above animal level, reducing pipe contamination risks but requiring additional vacuum power. Both approaches integrate with various parlor configurations and can accommodate different herd sizes.

Pipeline systems offer excellent milk quality control through reduced air exposure and contamination opportunities. The sealed transport system maintains milk temperature and prevents foreign matter introduction. However, these systems require careful cleaning protocols and regular maintenance to ensure optimal performance and food safety compliance.

Bucket Milking: Portable Solutions

Bucket milking systems provide portable milking capabilities using vacuum-powered units that collect milk in individual buckets or containers. These systems prove ideal for small to medium-sized operations that require flexibility without the infrastructure investment of fixed installations.

Modern bucket systems often incorporate milk meters, automatic shut-offs, and sanitary fittings that maintain milk quality while providing operational convenience. The portability allows farmers to adapt to different facility configurations and animal housing systems.

While bucket systems require more labor for milk handling and transport compared to pipeline systems, they offer lower initial costs and greater operational flexibility. These characteristics make bucket systems attractive for beginning farmers, seasonal operations, and specialized dairy enterprises.

Specialized Milking Applications

Beyond traditional cow milking, various specialized applications require adapted techniques and equipment. Goat milking often employs scaled-down versions of cow milking systems, with modifications for smaller udder size and different anatomy. Sheep milking utilizes specialized equipment designed for the unique characteristics of ovine milk production.

Buffalo, yak, and other alternative dairy species require specific adaptations in milking techniques and equipment design. These applications often combine traditional methods with modern technology to address unique challenges posed by different animal species and production environments.

Factors Influencing Milking Method Selection

Several critical factors influence the choice of milking method for any given operation. Herd size remains the primary consideration, with hand milking practical only for very small herds, while robotic systems become economically viable only with sufficient animal numbers.

Available capital significantly impacts system selection, as advanced automated systems require substantial upfront investments. Labor availability and costs also influence decisions, with automated systems potentially offsetting high labor costs in regions with expensive or scarce workers.

Facility constraints, including building size, electrical capacity, and water availability, may limit system options. Geographic location affects equipment availability, service support, and operating costs. Animal welfare considerations increasingly influence system selection, with emphasis on reducing stress and improving cow comfort.

Future Trends in Milking Technology

The dairy industry continues evolving toward greater automation, precision, and sustainability. Artificial intelligence integration promises more sophisticated animal monitoring and predictive health management. Sensors capable of real-time milk composition analysis may enable immediate quality assessment and pricing adjustments.

Sustainability concerns drive development of energy-efficient systems and waste reduction technologies. Water conservation becomes increasingly important, leading to innovations in cleaning system design and water recycling capabilities.

Precision dairy farming concepts integrate milking systems with comprehensive herd management platforms, creating holistic approaches to dairy production optimization. These developments promise improved animal welfare, environmental sustainability, and economic efficiency.

Frequently Asked Questions

Q: What is the most efficient type of milking system for a medium-sized dairy farm? A: For medium-sized operations (50-200 cows), herringbone or parallel parlor systems typically provide the best balance of efficiency, cost, and labor management. These systems allow milking multiple animals simultaneously while maintaining reasonable equipment costs and operational complexity.

Q: How often should dairy cows be milked regardless of the system used? A: Most dairy cows are milked twice daily, approximately 12 hours apart. However, high-producing cows may benefit from three-times-daily milking, while robotic systems allow flexible milking schedules based on individual animal needs and production levels.

Q: Can different types of milking systems be combined on the same farm? A: Yes, many farms use hybrid approaches combining different milking methods. For example, a farm might use a parlor system for the main herd while employing hand milking or bucket systems for sick animals, fresh cows, or special-needs animals requiring individual attention.

Q: What factors determine milk quality across different milking methods? A: Milk quality depends primarily on hygiene practices, equipment maintenance, animal health, and proper milk handling rather than the specific milking method. All systems can produce high-quality milk when operated correctly with appropriate sanitation protocols.

Q: How do robotic milking systems affect animal behavior and welfare? A: Robotic systems often improve animal welfare by allowing cows to follow natural milking rhythms, reducing handling stress, and providing consistent, gentle milking procedures. However, successful implementation requires proper animal training and adaptation periods.

Q: What are the main maintenance requirements for different milking systems? A: All milking systems require regular cleaning, sanitization, and equipment inspection. More complex systems like robots and automated parlors need specialized technical maintenance, while simpler systems like hand milking require minimal equipment maintenance but more physical upkeep of facilities and tools.

Realistic Image Prompt: “A modern dairy farm showing multiple types of milking systems in action: farmers hand-milking Holstein cows in wooden stalls on one side, a herringbone milking parlor with cows being milked by machines in the center, and a robotic milking system with cows entering automated stalls on the right side, all in a clean, well-lit agricultural setting with hay bales and pastoral backgrounds”

Best Category: Agriculture & Farming